Phosphorus bronze, commonly referred to as Phos-bronze and sometimes Tin bronze, is a copper alloy used in manufacture products due to its low-wear properties.

This durable material is composed of copper, tin, and phosphorus. The composition of phosphorus bronze includes 0.50-11% tin and 0.01-0.35% phosphorus. Higher amounts of phosphorus increase the stiffness and wear resistance of the material, while tin aids in strength and corrosion resistance.

Phosphorous bronze is most generally used for electrical contacts, ship propellers, and certain dental bridges.

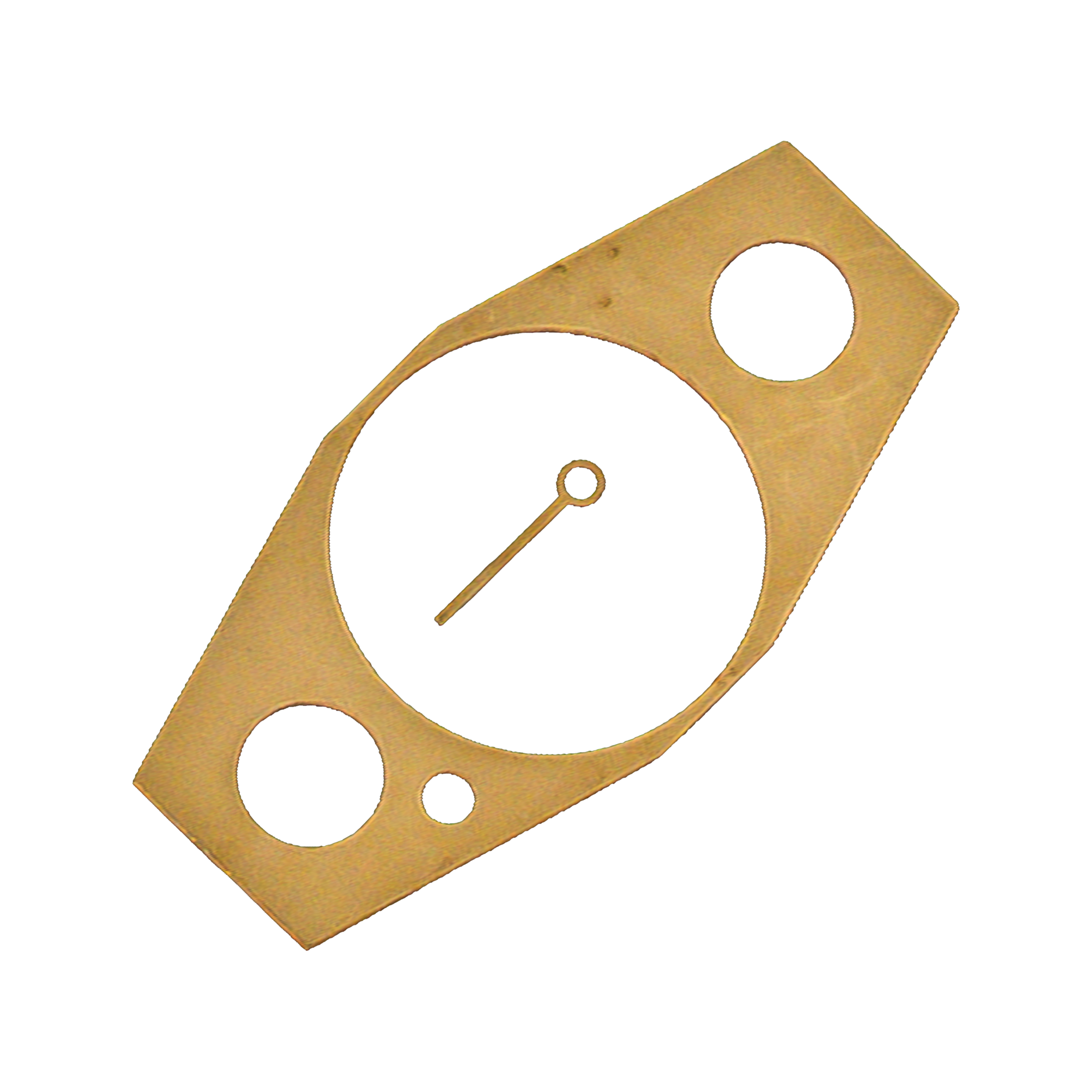

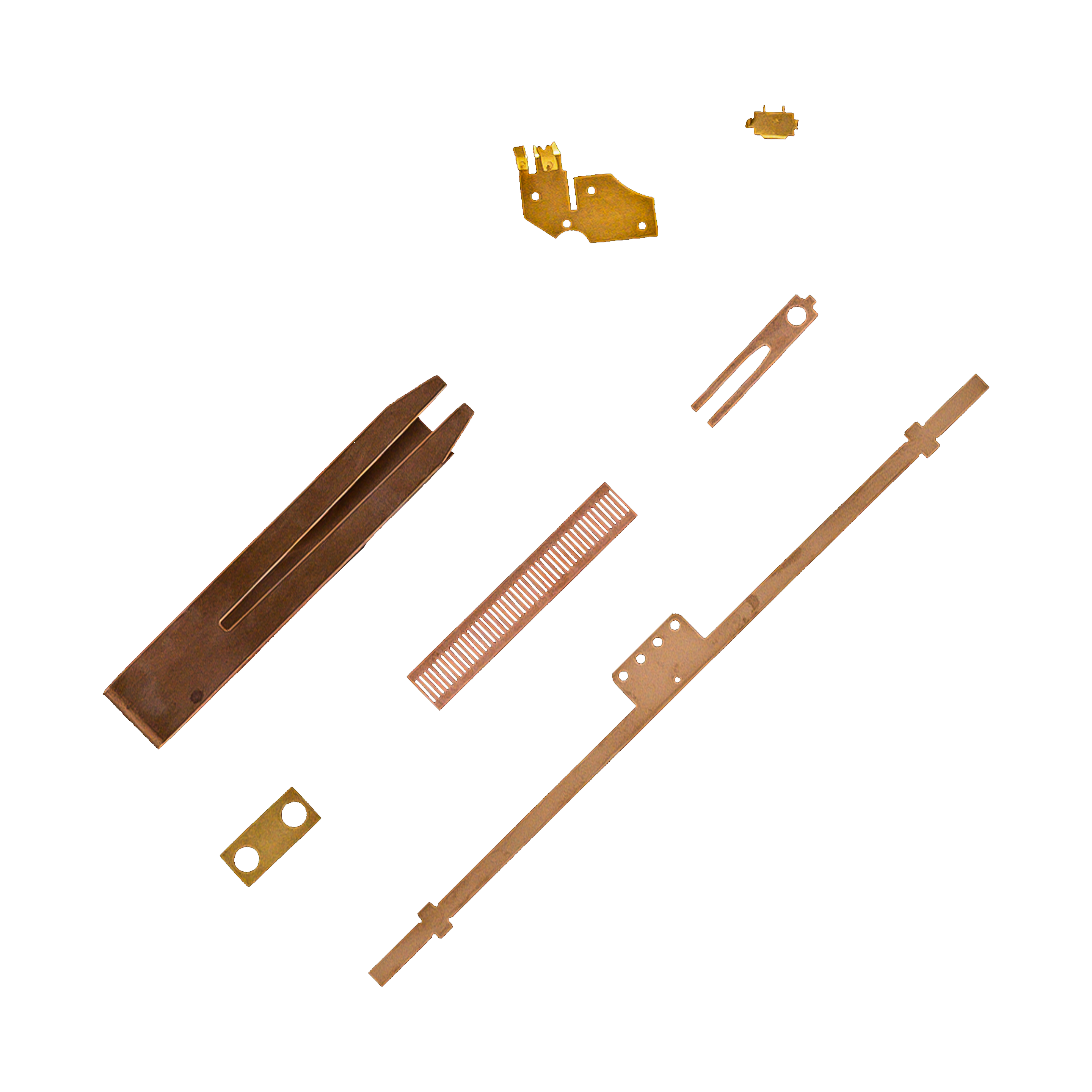

Microphoto produces unique parts using various alloys of Phosphor Bronze, including:

We take pride in using quality metals that are right for the job. Our phosphorous bronze parts prove to be consistent, durable, and high-quality. We also manage any post-production plating services that may be required.

At Microphoto, we provide customers with high-quality and high-precision parts through our photochemical machining process, also known as photochemical etching, metal etching, or chemical milling.

Photochemical machining allows for the manufacture of finely detailed and complex designs that could not be manufactured using other more traditional methods such as stamping. Our process results in parts that are burr-free, and without any recast layers that can result from laser cutting or WEDM processing.

Talk to a technical engineer about your project.