Since 1965, we have photochemically etched high-quality precision Aluminum parts for critical applications. At Microphoto, customer satisfaction is our utmost priority. Compliant with ISO9001, our robust quality management system ensures every etched-metal part meets applicable industry standards and project specifications. We are registered with the International Traffic in Arms Regulations, or ITAR, enabling us to perform etched-metal services for manufacturers that support U.S. military and space agencies.

We source from trustworthy mills, and compliance is verified upon arrival. Quality control personnel use precise testing and inspection equipment. All orders are audited for accuracy before shipment. Microphoto has quality and delivery ratings consistently exceeding 99%.

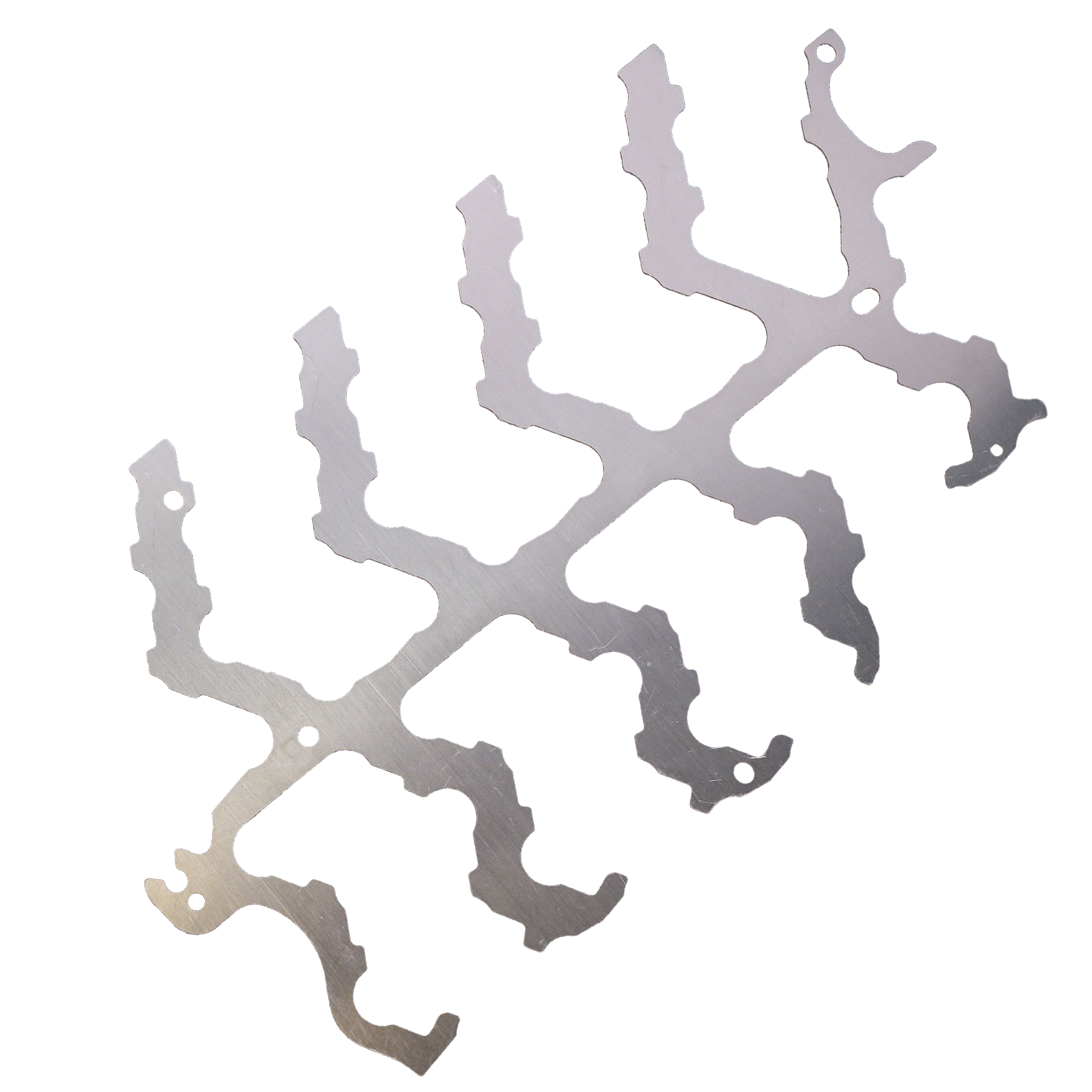

Our team transforms aluminum into precision parts with photochemical etching, which is also referred to as chemical etching or photo etching. In this process, chemical etchants are cut into unprotected areas of a metal surface to create a design or image according to your specifications.

Unlike traditional stamping, our process produces aluminum components that are burr-free, stress-free, and without any recast layers that can result from laser cutting or WEDM processing.

With a soft and silvery-white appearance, aluminum is considered the world’s most abundant metal. It naturally generates a protective thin oxide coating that protects against degradation. This material also has a long life and is completely recyclable, making it environmentally friendly.

Aluminum easily binds with other elements, such as iron, silicon, copper, magnesium, manganese, and zinc. As a result, alloyed aluminum has a range of characteristics.

Pure and alloyed aluminum is made into components found in everyday and critical applications, from automobile accessories and electrical wiring systems to appliances and aerospace parts. Here are common aluminum alloy grades:

This series of aluminum is the purest of all commercial grades. Material under this grade classification contains a minimum of 99 percent pure aluminum, which creates exceptional resistance properties.

This series of aluminum is alloyed with manganese and exhibits high strength. It also offers moderate resistance to chemical and atmospheric agents. It has better formability than pure aluminum. Common uses include cooking utensils, food-processing equipment, food-handling components, and automotive trim.

This series of aluminum contains high levels of magnesium and silicon and is corrosion-resistant. It’s a precipitation-hardened aluminum alloy that’s versatile and has good corrosion resistance, workability, machinability, and weldability.

The 2000 series is known as the copper grade of aluminum since the primary alloying element is copper. This addition increases strength and hardness, which improves machinability but results in low corrosion resistance. Typical uses include parts that require a high strength-to-weight ratio, such as aircraft structural components.

The 5000 series can’t undergo heat treatment. Alloyed with magnesium and chromium, this material exhibits excellent corrosion resistance. It has high fatigue strength, exceptional workability, and is typically used for aircraft components, home appliances, marine industry parts, and food processing equipment.

Etching aluminum requires precise process control and careful preparation to achieve accurate results without introducing heat-affected zones or structural weaknesses. Because aluminum is lightweight and offers high conductivity, it is widely used in electronics and micro components, especially in extreme environments where durability is critical.

Best practices include cleaning surfaces with acetone to remove contaminants, applying a high-quality photoresist, and selecting the right etchant to minimize interference and overcome material limitations. Compared to traditional stamping or printing, photo etching provides significant cost savings and consistent quality across production runs.

Microphoto specializes in precision aluminum etching, delivering parts with fine detail and burr-free finishes tailored to your application’s key requirements. For more information on how Microphoto can help with your aluminum part needs, get in contact with us today.

When applications require components manufactured from strong-but-lightweight materials, aluminum and its alloys are often the metals of choice. Turning this high-performance material into precision piece parts can be tough, however.

Manufacturing with aluminum can cause a number of obstacles, such as Aluminum’s ductility causing galling and pick-up when machined, high heat reflectivity making it challenging to laser cut, and the material also work-hardening when punched. These issues can lead to nonconforming products, which can cause unwanted downtime or, worse, premature failure.

With Microphoto, however, these issues are of no concern. Our innovative photochemical etching process means we can achieve highly precise results that allow engineers to create complex designs without compromise. We carefully prepare each project, discuss requirements with clients, and fix potential challenges before we start to etch.

Contact us today!

Talk to a technical engineer about your project.