Phosphorus bronze, commonly referred to as Phos-bronze and sometimes Tin bronze, is a copper alloy used in manufactured products due to its low-wear properties and suitability for bronze etching.

This durable material is composed of copper, tin, and phosphorus. The etching process with phosphorus bronze allows for the creation of complex patterns and intricate designs in precision parts. The composition of phosphorus bronze includes 0.50-11% tin and 0.01-0.35% phosphorus. Higher amounts of phosphorus increase the stiffness and wear resistance of the material, while tin aids in strength and corrosion resistance.

Phosphorous bronze is most generally used for electrical contacts, ship propellers, and certain dental bridges. These applications benefit from reliable etched pieces that combine durability with fine detail.

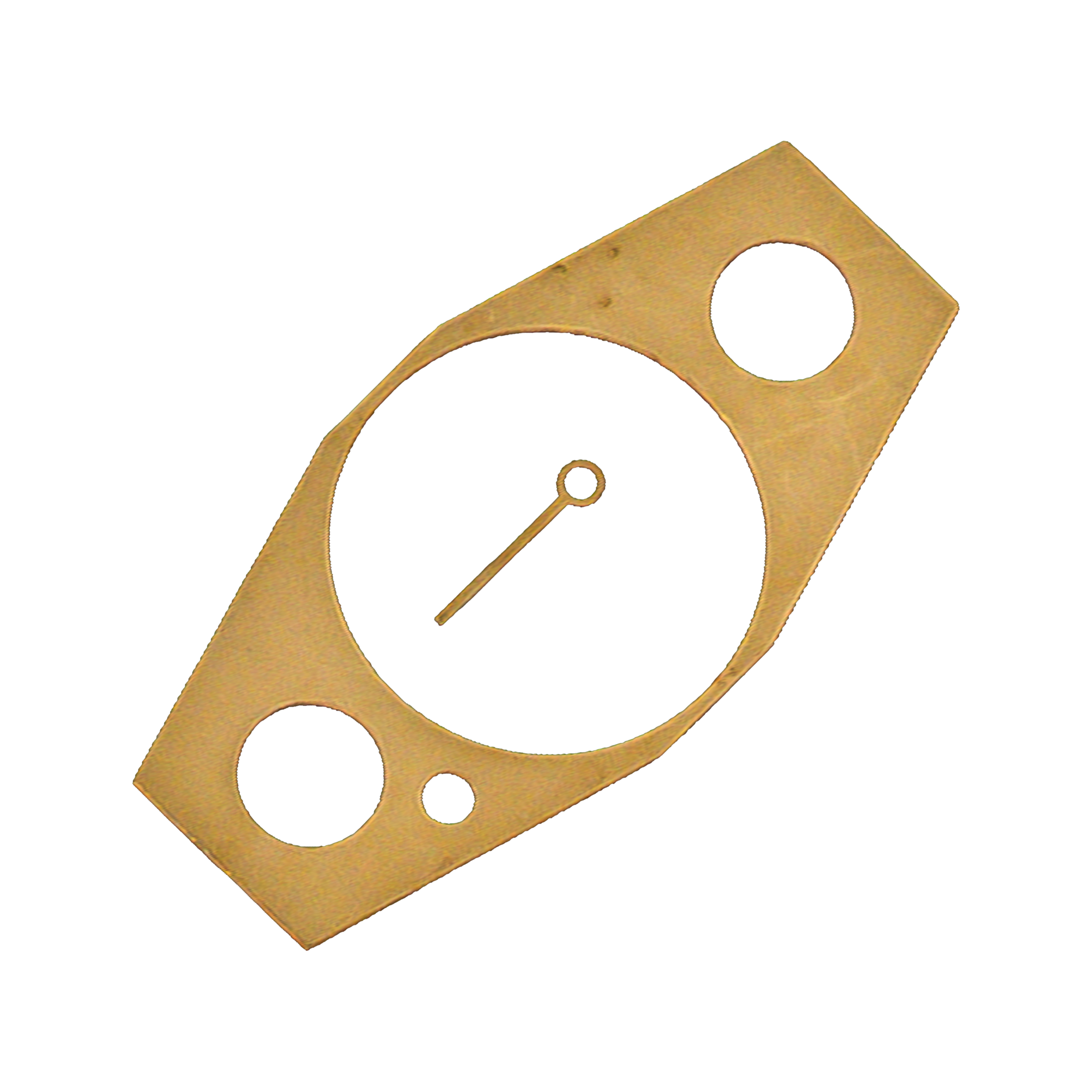

Microphoto’s bronze etching process is regarded as the best method for producing precision components with clean edges and a smooth surface finish. Using a carefully controlled etching bath with ferric chloride as the etchant, bronze parts are processed in a plastic container to ensure safety and consistency.

By maintaining the correct temperature and chemical solution balance, the process prevents buildup and delivers high-quality parts that remain completely burr free. This approach allows us to precisely form intricate bronze components, combining durability with exceptional accuracy for demanding applications.

Microphoto’s bronze etching process is regarded as the best method for producing precision components with clean edges and a smooth surface finish. Using a carefully controlled etching bath with ferric chloride as the etchant, bronze parts are processed in a plastic container to ensure safety and consistency.

By maintaining the correct temperature and chemical solution balance, the process prevents buildup and delivers high-quality parts that remain completely burr free. This approach allows us to precisely form intricate bronze components, combining durability with exceptional accuracy for demanding applications.

Phosphor bronze is often compared to brass and steel because of its strength, durability, and resistance to wear. While each material has its advantages, phosphor bronze stands out for its balance of toughness, corrosion resistance, and workability, making it a preferred choice in demanding applications.

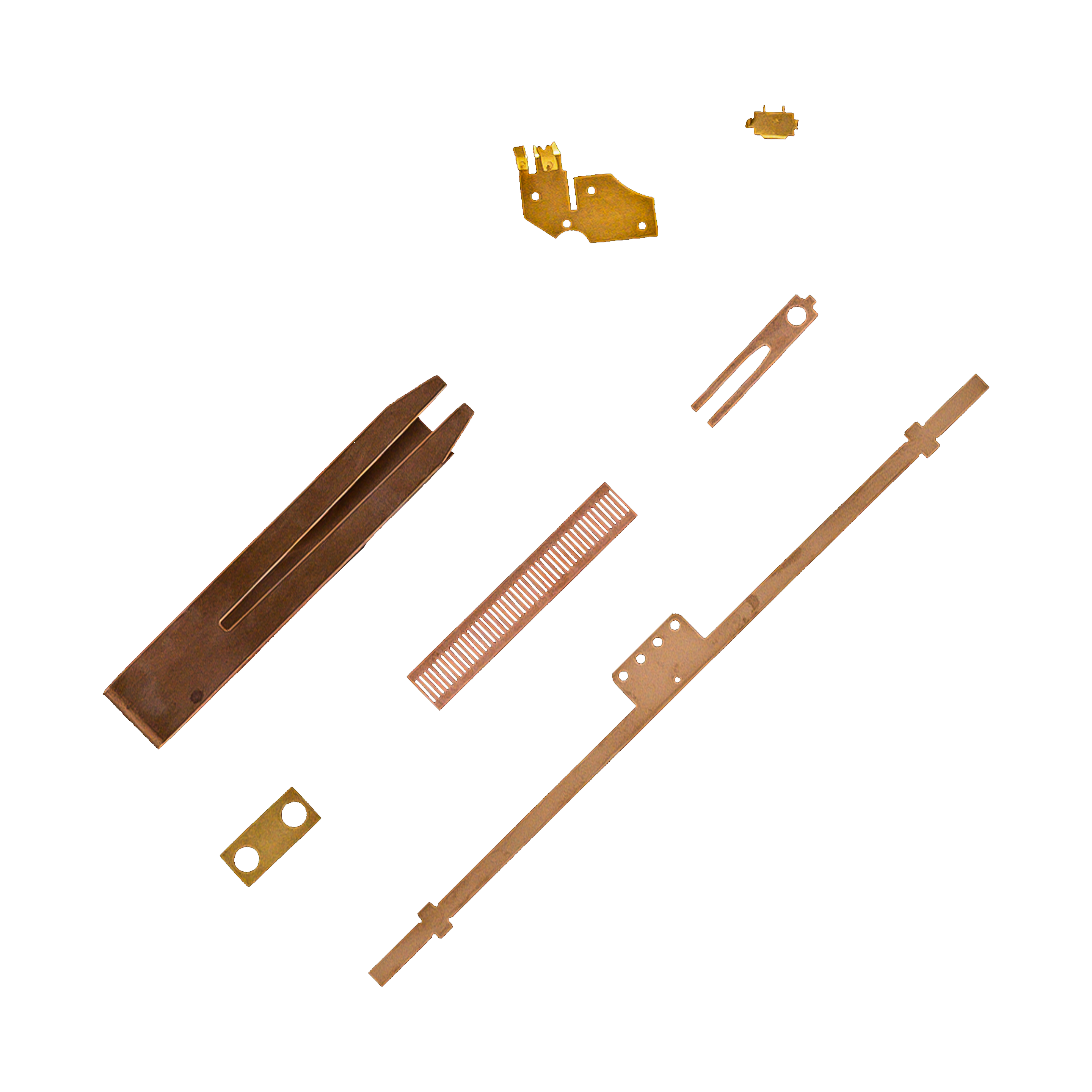

Etched bronze parts are valued across industries for their reliability, durability, and ability to be produced with fine detail. Thanks to their excellent wear resistance, conductivity, and formability, they are used in a wide range of applications, from everyday components to specialised industrial solutions.

small and gold colored photo etched parts for electronic components

At Microphoto, we provide customers with high-quality and high-precision parts through our photochemical machining process, also known as photochemical etching, metal etching, or chemical milling.

Photochemical machining allows for the manufacture of finely detailed and complex designs that could not be manufactured using other, more traditional methods, such as stamping. Our process results in parts that are burr-free and without any recast layers that can result from laser cutting or WEDM processing.

Talk to a technical engineer about your project.